Plastex Plastic in Vette Magazine

GIVING YOUR CORVETTE'S BODYWORK A FACELIFT CAN BE EASIER THAN YOU THINK

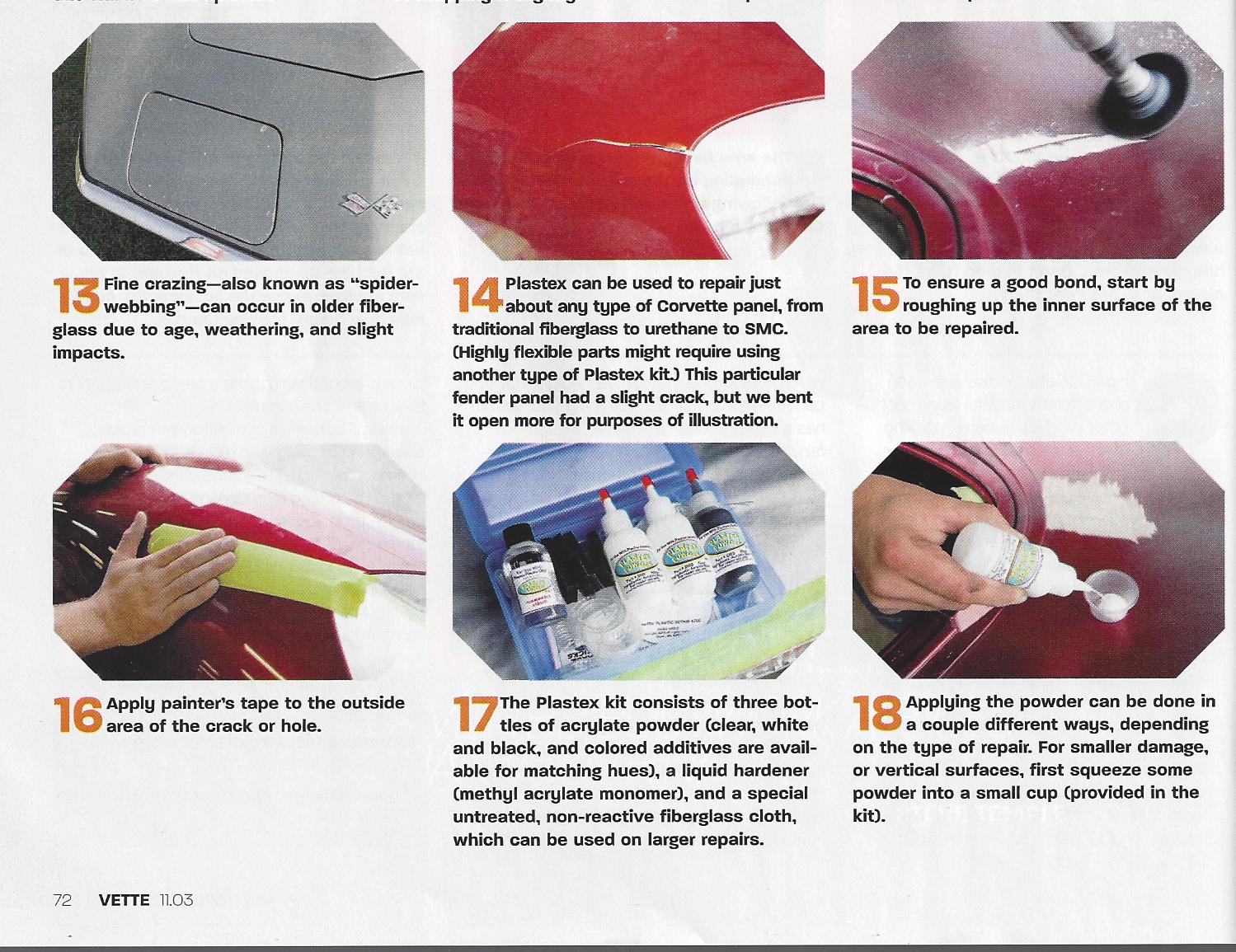

Since Corvette bodies are made of a different material than most other production cars, repairing minor damage can require alternative materials and techniques. While fiberglass and SMC (Sheet Molded Compound, which is found on later models) have the advantage of being rustproof, such composites are subject to their own sets of problems. These range from crazing (also called "spider webbing") to cracking, usually from a slight impact. More-severe or widespread body damage may require the complete replacement of large components - a job best left to pro - so we'll limit our focus on minor damage that can be repaired in your own driveway.

We'll start with a slight surface imperfections. If polishing and waxing isn't producing the smooth finish you'd like to see on your beloved Corvette, consider using 3M Scratch Remover, which is designed to minimize defects that don't penetrate the clearcoat (assuming your vehicle has a two-part urethane paint). This product is fairly simple to use, requiring only three separate steps and common household drill. We tried the 3M product on a C5 that had a few scratches on it, and they all but disappeared.

For cracks or crazing (the latter is usually seen on older fiberglass bodies), a type of adhesive called Plastex can repair a wide range of materials. In addition to fixing fiberglass or SMC, it can be used to fabricate small components, or even metal (using a slightly different version of the repair kit).

The inventor of Plastex, Tim Lewis of G.T. Motorsports, has some pretty impressive credentials in chemical engineering. In addition to being trained at the Northrop Institute of Technology, he's worked on the adhesive tiles used on NASA's space shuttle, and served as manager of Harrah's car collection. So he knows his way around composite materials and hot to take are of fine automobiles.

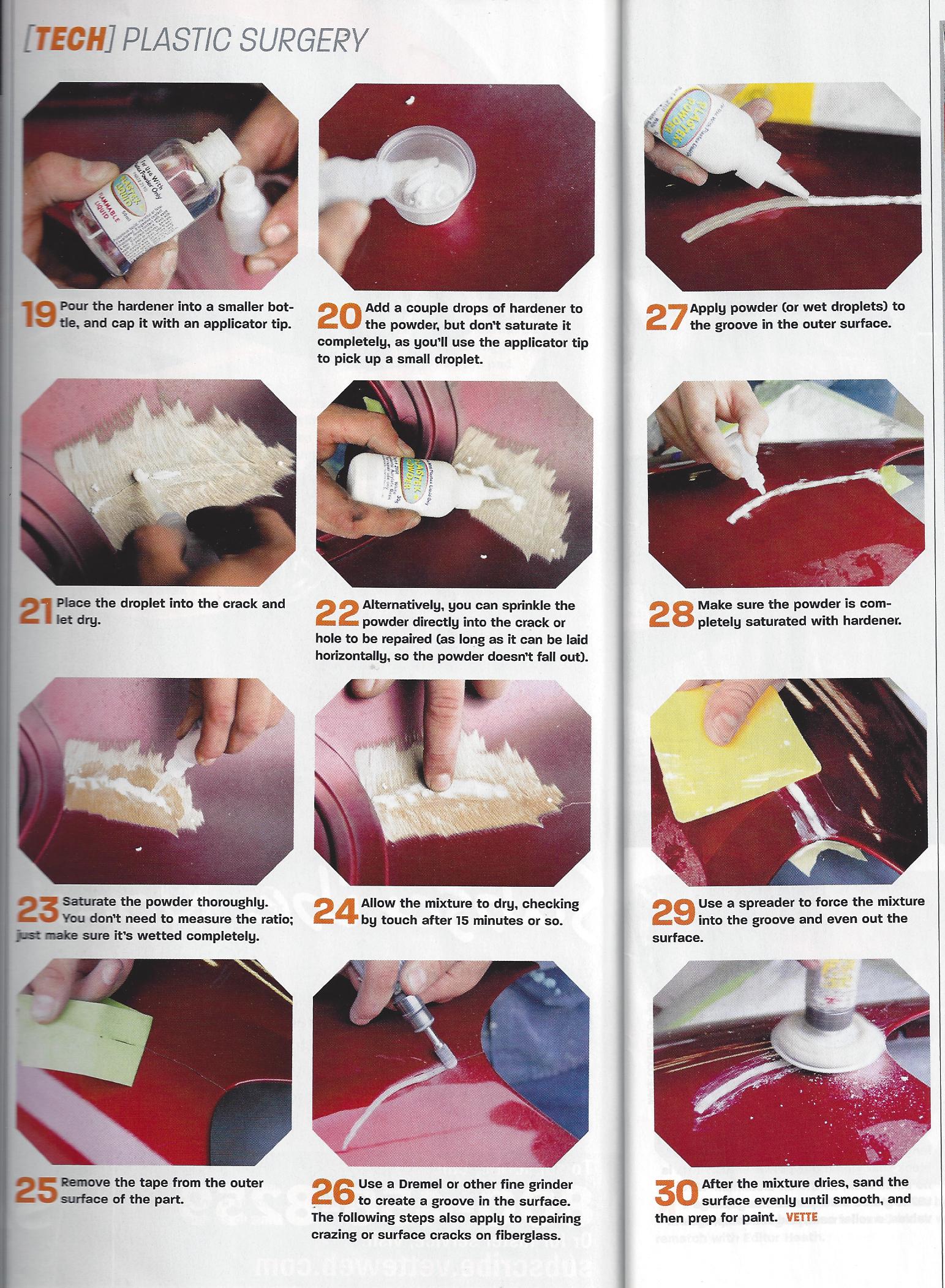

Using Plastex is a straightforward process, easier than working with resin and fiberglass. Unlike conventional resin and catalyst, form most repairs the mixing ration doesn't have to be in precise proportions, as long as the powder is thoroughly saturated. Depending on the type of damage, Plastex powder can be used with or without the cloth included in the kit, and it dries very quickly in a variety of weather conditions, so that you can sand it and prep for paint in short order.